Industrial Biomass Boiler

Industrial Biomass Boiler

Industrial biomass boiler is using biomass energy as fue. It is divided into biomass steam boiler, biomass hot water boiler, biomass hot air stove, biomass thermal oil heater, etc.

In terms of structural design of the boiler, the space of the furnace is relatively large compared to the traditional boiler, a very reasonable secondary air is arranged, which is conducive to the combustion of a large amount of volatile matter that is instantaneously released during the combustion of biomass fuel.

The boiler can be equipped with fuel (gas) ignition burner to realize ignition automation. Our biomass boiler has highly automatic system of feeding, combustion, slag removal, water feeding, and ignition can be automatically controlled, which is very convenient to operate. The boiler is equipped with an automatic ash cleaning device, which can timely remove the ash deposit on the heating surface of the boiler to ensure the efficient and stable operation of the boiler. An economizer is arranged at the tail of the boiler, and an air preheater can also be arranged according to user needs.

Industrial Biomass Hot Water Boiler

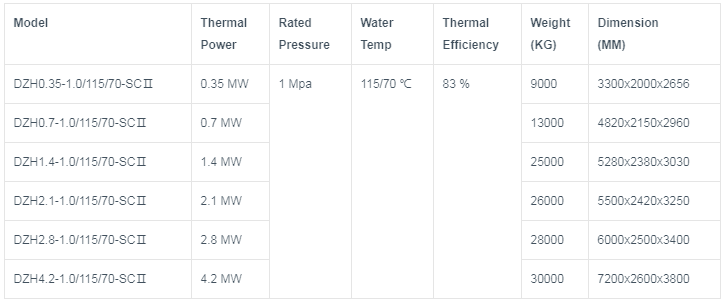

DZH Manul Feeding

Biomass Hot Water Boiler

- Thermal Power: 0.35~4.2MW

- Rated Pressure: 0 Mpa, 1.0 Mpa

- Water Temperature: 85 ℃, 0Mpa

- Water Temperature: 115 ℃, 1.0Mpa

- Thermal Efficiency: >83%

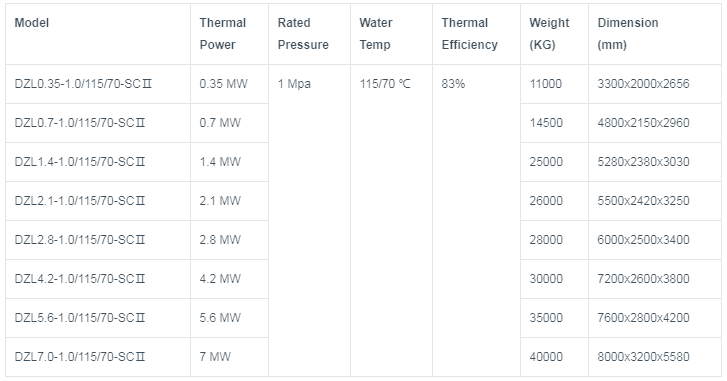

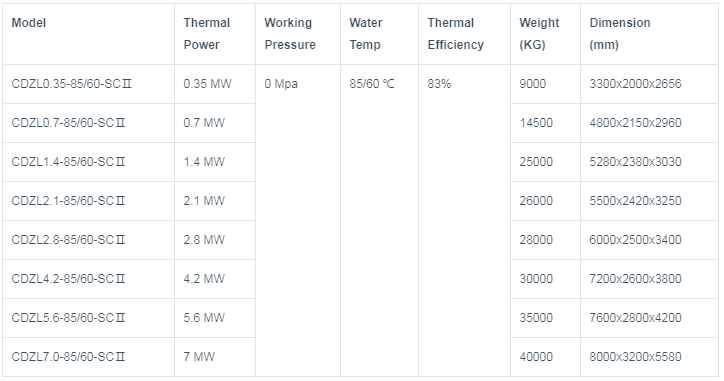

DZL Chain Grate

Biomass Hot Water Boiler

- Thermal Power: 0.35~7MW

- Rated Pressure: 0 Mpa, 1.0 Mpa

- Water Temperature: 85 ℃, 0Mpa

- Water Temperature: 115 ℃, 1.0Mpa

- Thermal Efficiency: >83%

SZL Double Drum Chain Grate

Biomass Hot Water Boiler

- Thermal Power: 4.2~14MW

- Rated Pressure: 0 Mpa, 1.0 Mpa

- Water Temperature: 85 ℃, 0Mpa

- Water Temperature: 115 ℃, 1.0Mpa

- Thermal Efficiency: >83%

Industrial Biomass Steam Boiler

Industrial Biomass Boiler Product List

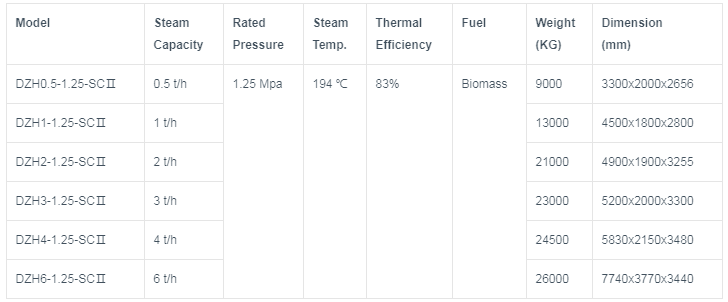

DZH model manual feeding industrial biomass boiler is a single-tube vertical biomass boiler. It is a horizontal three-pass water-fired tube boiler, which promotes the combustion of fuel to the greatest extent and makes the thermal efficiency more than 82.6%. Yongxing DZH series boiler is equipped with a draft fan for mechanical ventilation, complete control and monitoring instruments, and safe and reliable operation.

Performance Advantages:

1. The boiler runs smoothly and the failure rate is low.

2. Our biomass boiler is packed with 304 stainless steel, which is very beautiful and durable.

3. This bioler use self cleaning threaded pipe, which reduces the workload of cleaning.

4. The burned ash can also be used as farm manure, which can reduce the cost and reduce the investment of the enterprise.

5. Solving the problems of ash and slagging during combustion and heat exchange, enabling the boiler run safely for a long time.

6. A dust collector is arranged at the tail flue to ensure that the dust emission meets environmental protection requirements.

| Model | Steam Capacity | Rated Pressure | Steam Temp. | Thermal Efficiency | Fuel | Weight (KG) | Dimension (mm) |

| DZH0.5-1.25-SCⅡ | 0.5 t/h | 1.25 Mpa | 194 ℃ | 83% | Biomass | 9000 | 3300x2000x2656 |

| DZH1-1.25-SCⅡ | 1 t/h | 13000 | 4500x1800x2800 | ||||

| DZH2-1.25-SCⅡ | 2 t/h | 21000 | 4900x1900x3255 | ||||

| DZH3-1.25-SCⅡ | 3 t/h | 23000 | 5200x2000x3300 | ||||

| DZH4-1.25-SCⅡ | 4 t/h | 24500 | 5830x2150x3480 | ||||

| DZH6-1.25-SCⅡ | 6 t/h | 26000 | 7740x3770x3440 |

| Model | Thermal Power | Rated Pressure | Water Temp | Thermal Efficiency | Weight (KG) | Dimension (MM) |

| DZH0.35-1.0/115/70-SCⅡ | 0.35 MW | 1 Mpa | 115/70 ℃ | 83 % | 9000 | 3300x2000x2656 |

| DZH0.7-1.0/115/70-SCⅡ | 0.7 MW | 13000 | 4820x2150x2960 | |||

| DZH1.4-1.0/115/70-SCⅡ | 1.4 MW | 25000 | 5280x2380x3030 | |||

| DZH2.1-1.0/115/70-SCⅡ | 2.1 MW | 26000 | 5500x2420x3250 | |||

| DZH2.8-1.0/115/70-SCⅡ | 2.8 MW | 28000 | 6000x2500x3400 | |||

| DZH4.2-1.0/115/70-SCⅡ | 4.2 MW | 30000 | 7200x2600x3800 |

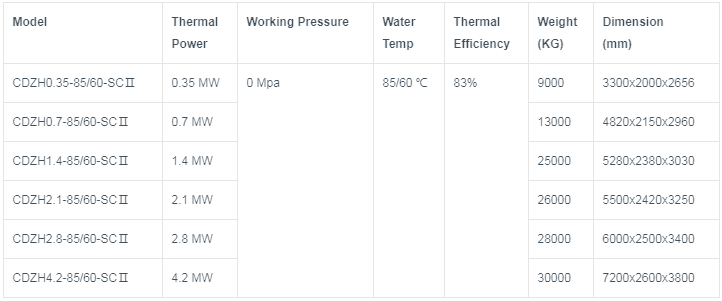

| Model | Thermal Power | Working Pressure | Water Temp | Thermal Efficiency | Weight (KG) | Dimension (mm) |

| CDZH0.35-85/60-SCⅡ | 0.35 MW | 0 Mpa | 85/60 ℃ | 83% | 9000 | 3300x2000x2656 |

| CDZH0.7-85/60-SCⅡ | 0.7 MW | 13000 | 4820x2150x2960 | |||

| CDZH1.4-85/60-SCⅡ | 1.4 MW | 25000 | 5280x2380x3030 | |||

| CDZH2.1-85/60-SCⅡ | 2.1 MW | 26000 | 5500x2420x3250 | |||

| CDZH2.8-85/60-SCⅡ | 2.8 MW | 28000 | 6000x2500x3400 | |||

| CDZH4.2-85/60-SCⅡ | 4.2 MW | 30000 | 7200x2600x3800 |

DZH Manual Feeding Biomass Boiler

The DZL biomass boiler adopts a single-tube vertical structure and chain grate combustion. It has advantages of the following:

1. The use of threaded smoke pipe for heat transfer which greatly improves thermal efficiency and reduces energy consumption.

2. The design of two-wing flues allows the flue gas to enter the front smoke box smoothly, so that the temperature of the previous tube and sheet is the same, and the tube sheet crack due to temperature difference is avoided.

3. The threaded smoke pipe is designed inside the boiler shell, there is little overall leakage, and the only a litte heat loss of the exhaust smoke.

4. The longitudinal and welding seams of the boiler adopt advanced submerged arc automatic welding technology, which guarantees the welding quality.

5. The application of membrane water-cooled wall structure improves the heat transfer coefficient and heat transfer effect, and reduces heat loss.

6. The grate adopts a new type of small-scale grate, which adds a unique safety ring to make the grate operate stably and reliably and improve the combustion efficiency.

7. The advanced arch-shaped design forms an obviously inverted “α” flame, which is beneficial to the combustion and has strong adaptability to biomass fuel types.

8. Complete control and monitoring instruments, safe and reliable boiler operation

9. A dust collector is arranged at the tail flue to ensure that the dust emission meets environmental protection requirements.

10. High level of automation, with functions such as automatic water adjustment, low water level interlock protection, high and low water level alarms, etc.

DZL Biomass Chain Grate Water Boiler

| Model | Steam Capacity | Rated Pressure | Steam Temp. | Thermal Efficiency | Fuel | Weight (KG) | Dimension (mm) |

| DZL0.5-1.25-SCⅡ | 0.5 t/h | 1.25 Mpa | 194℃ | 83 % | Wood Biomass Solid Fule | 11000 | 3300x2000x2656 |

| DZL1-1.25-SCⅡ | 1 t/h | 15000 | 5200x2100x2600 | ||||

| DZL2-1.25-SCⅡ | 2 t/h | 23000 | 5650x2400x2700 | ||||

| DZL3-1.25-SCⅡ | 3 t/h | 24000 | 5700x2600x2800 | ||||

| DZL4-1.25-SCⅡ | 4 t/h | 29000 | 6850x2700x3200 | ||||

| DZL6-1.25-SCⅡ | 6 t/h | 32000 | 6800x2900x3400 | ||||

| DZL8-1.25-SCⅡ | 8 t/h | 35000 | 7200x3200x3800 | ||||

| DZL10-1.25-SCⅡ | 10 t/h | 40000 | 7900x3400x5500 |

| Model | Thermal Power | Rated Pressure | Water Temp | Thermal Efficiency | Weight (KG) | Dimension (mm) |

| DZL0.35-1.0/115/70-SCⅡ | 0.35 MW | 1 Mpa | 115/70 ℃ | 83% | 11000 | 3300x2000x2656 |

| DZL0.7-1.0/115/70-SCⅡ | 0.7 MW | 14500 | 4800x2150x2960 | |||

| DZL1.4-1.0/115/70-SCⅡ | 1.4 MW | 25000 | 5280x2380x3030 | |||

| DZL2.1-1.0/115/70-SCⅡ | 2.1 MW | 26000 | 5500x2420x3250 | |||

| DZL2.8-1.0/115/70-SCⅡ | 2.8 MW | 28000 | 6000x2500x3400 | |||

| DZL4.2-1.0/115/70-SCⅡ | 4.2 MW | 30000 | 7200x2600x3800 | |||

| DZL5.6-1.0/115/70-SCⅡ | 5.6 MW | 35000 | 7600x2800x4200 | |||

| DZL7.0-1.0/115/70-SCⅡ | 7 MW | 40000 | 8000x3200x5580 |

| Model | Thermal Power | Working Pressure | Water Temp | Thermal Efficiency | Weight (KG) | Dimension (mm) |

| CDZL0.35-85/60-SCⅡ | 0.35 MW | 0 Mpa | 85/60 ℃ | 83% | 9000 | 3300x2000x2656 |

| CDZL0.7-85/60-SCⅡ | 0.7 MW | 14500 | 4800x2150x2960 | |||

| CDZL1.4-85/60-SCⅡ | 1.4 MW | 25000 | 5280x2380x3030 | |||

| CDZL2.1-85/60-SCⅡ | 2.1 MW | 26000 | 5500x2420x3250 | |||

| CDZL2.8-85/60-SCⅡ | 2.8 MW | 28000 | 6000x2500x3400 | |||

| CDZL4.2-85/60-SCⅡ | 4.2 MW | 30000 | 7200x2600x3800 | |||

| CDZL5.6-85/60-SCⅡ | 5.6 MW | 35000 | 7600x2800x4200 | |||

| CDZL7.0-85/60-SCⅡ | 7 MW | 40000 | 8000x3200x5580 |

DZL Biomass Chain Grate Water Boiler

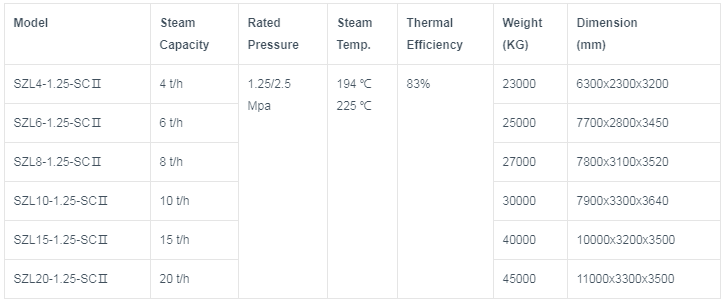

SZL industrial biomass fired boiler adopts double-cylinder vertical structure. There are water cooled walls in front and around the boiler. The upper part is connected with the cylinder and the lower part is connected with the header to form a combustion chamber to absorb the furnace heat radiation. There are dense convection tube bundle between the upper and lower boiler cylinder. The high-temperature flue gas after combustion passes through the secondary return stroke to horizontally flush the convective heating surface and is led to a separate economizer, and finally enters the dust collector and is discharged through the chimney.

Advantages and Features:

1. The convection arrangement has high heat exchange efficiency on the heating surface, and the boiler runs smoothly.

2. Chain grate, front and rear smoke box are all cut by CNC plasma cutting machine, neat and beautiful.

3. The boiler has a large volume capacity and complete internal devices.

4. The boiler has the functions of automatic adjustment of water supply, automatic alarm of high and low water levels, automatic protection of overpressure, and automatic protection of flameout.

5. The amount of air required for different fuels and different combustion stages in each air chamber can be adjusted, and the lateral wind pressure is the same, and the partial burning phenomenon will not occur.

6. The reasonable design of front and rear arches, the coverage of the furnace arch is large, and the furnace temperature is high;

7. Double-cylinder designed, high combustion efficiency, saving 5-10% of costs.

8. The cross-section ratio between the falling surface of each heating surface and the rising pipe is reasonable, and the combustion conditions are stable.

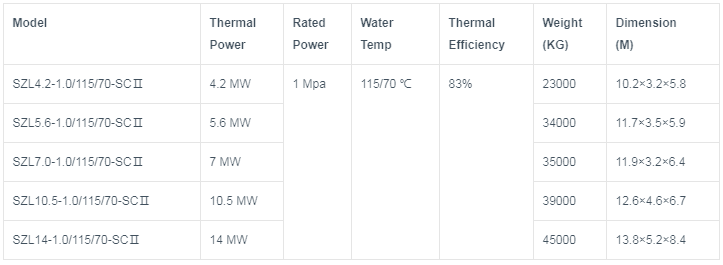

SZL Industrial Biomass Boiler

| Model | Steam Capacity | Rated Pressure | Steam Temp. | Thermal Efficiency | Weight (KG) | Dimension (mm) |

| SZL4-1.25-SCⅡ | 4 t/h | 1.25/2.5 Mpa | 194 ℃ 225 ℃ | 83% | 23000 | 6300x2300x3200 |

| SZL6-1.25-SCⅡ | 6 t/h | 25000 | 7700x2800x3450 | |||

| SZL8-1.25-SCⅡ | 8 t/h | 27000 | 7800x3100x3520 | |||

| SZL10-1.25-SCⅡ | 10 t/h | 30000 | 7900x3300x3640 | |||

| SZL15-1.25-SCⅡ | 15 t/h | 40000 | 10000x3200x3500 | |||

| SZL20-1.25-SCⅡ | 20 t/h | 45000 | 11000x3300x3500 |

| Model | Thermal Power | Rated Power | Water Temp | Thermal Efficiency | Weight (KG) | Dimension (M) |

| SZL4.2-1.0/115/70-SCⅡ | 4.2 MW | 1 Mpa | 115/70 ℃ | 83% | 23000 | 10.2×3.2×5.8 |

| SZL5.6-1.0/115/70-SCⅡ | 5.6 MW | 34000 | 11.7×3.5×5.9 | |||

| SZL7.0-1.0/115/70-SCⅡ | 7 MW | 35000 | 11.9×3.2×6.4 | |||

| SZL10.5-1.0/115/70-SCⅡ | 10.5 MW | 39000 | 12.6×4.6×6.7 | |||

| SZL14-1.0/115/70-SCⅡ | 14 MW | 45000 | 13.8×5.2×8.4 |

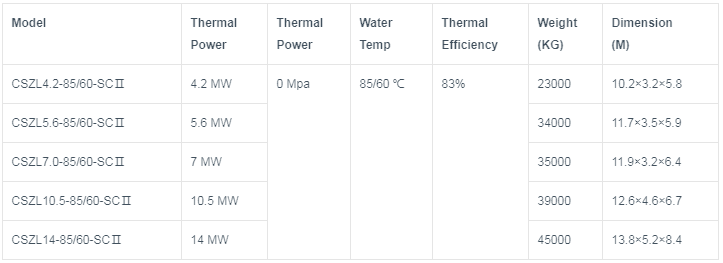

| Model | Thermal Power | Thermal Power | Water Temp | Thermal Efficiency | Weight (KG) | Dimension (M) |

| CSZL4.2-85/60-SCⅡ | 4.2 MW | 0 Mpa | 85/60 ℃ | 83% | 23000 | 10.2×3.2×5.8 |

| CSZL5.6-85/60-SCⅡ | 5.6 MW | 34000 | 11.7×3.5×5.9 | |||

| CSZL7.0-85/60-SCⅡ | 7 MW | 35000 | 11.9×3.2×6.4 | |||

| CSZL10.5-85/60-SCⅡ | 10.5 MW | 39000 | 12.6×4.6×6.7 | |||

| CSZL14-85/60-SCⅡ | 14 MW | 45000 | 13.8×5.2×8.4 |

SZL Industrial Biomass Boiler

Industrial Biomass Boiler Manufacturing Equipment