Thermal Oil Heater

Thermal Oil Heater

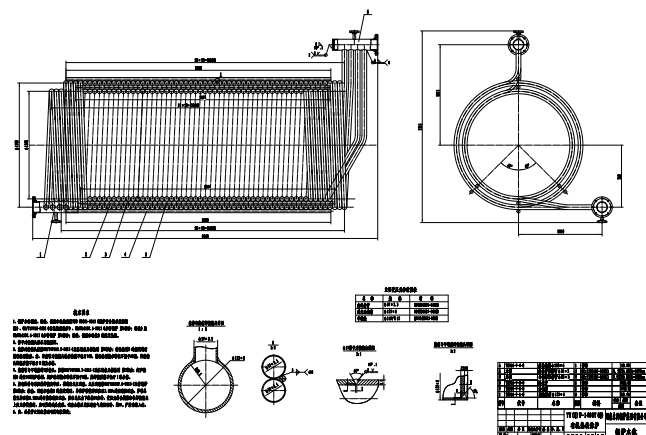

Thermal oil heater is a new type of hot oil heating system. It uses coal, oil, gas and biomass as fuel and flue gas as heat source, and heat transfer oil as heat carrier. High temperature thermal fluid is delivered to the heating equipment, and then returned to the heating furnace to be heated again, thermal fluid heater is a low-pressure, energy-saving equipment. The heating temperature can be as high as 340 ℃, and it is generally below the operating pressure of 1.0MPa.

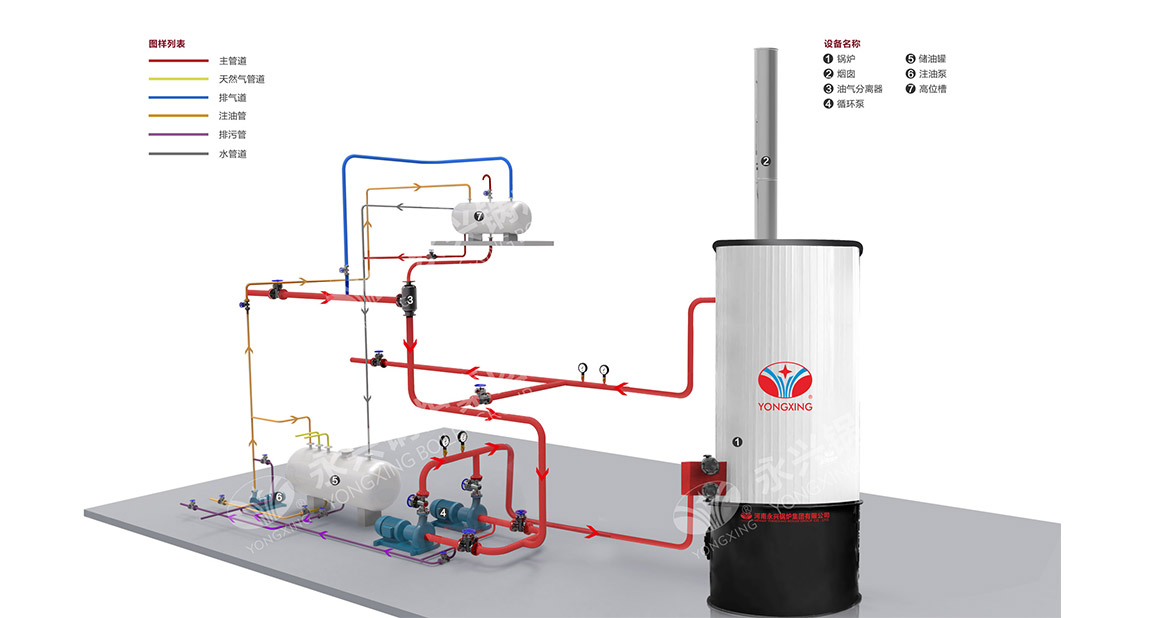

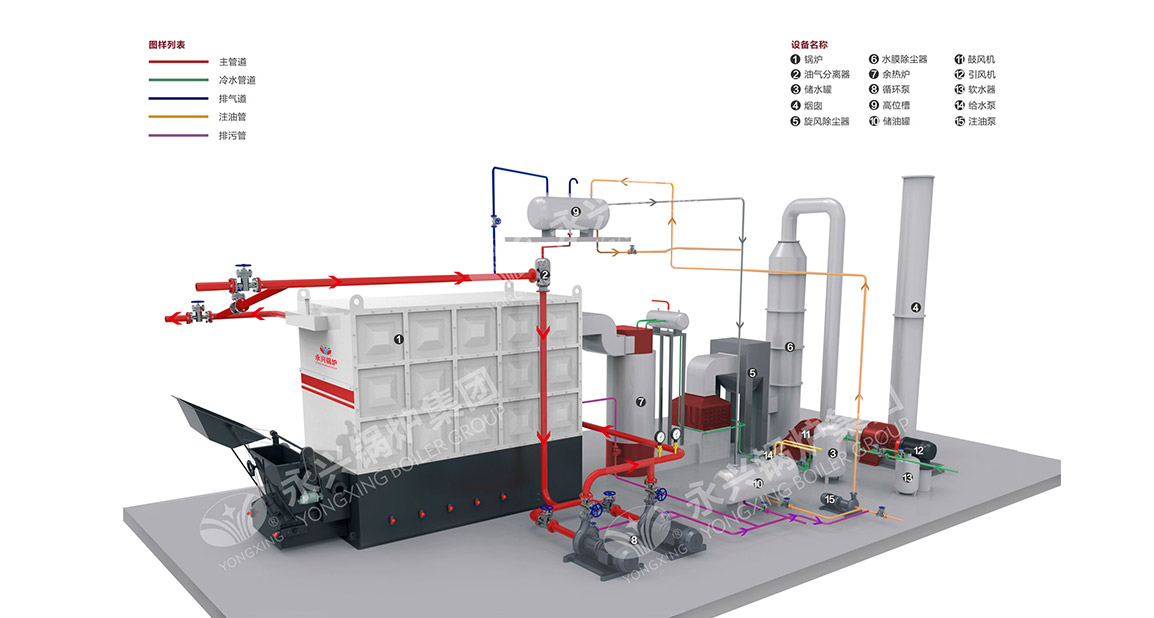

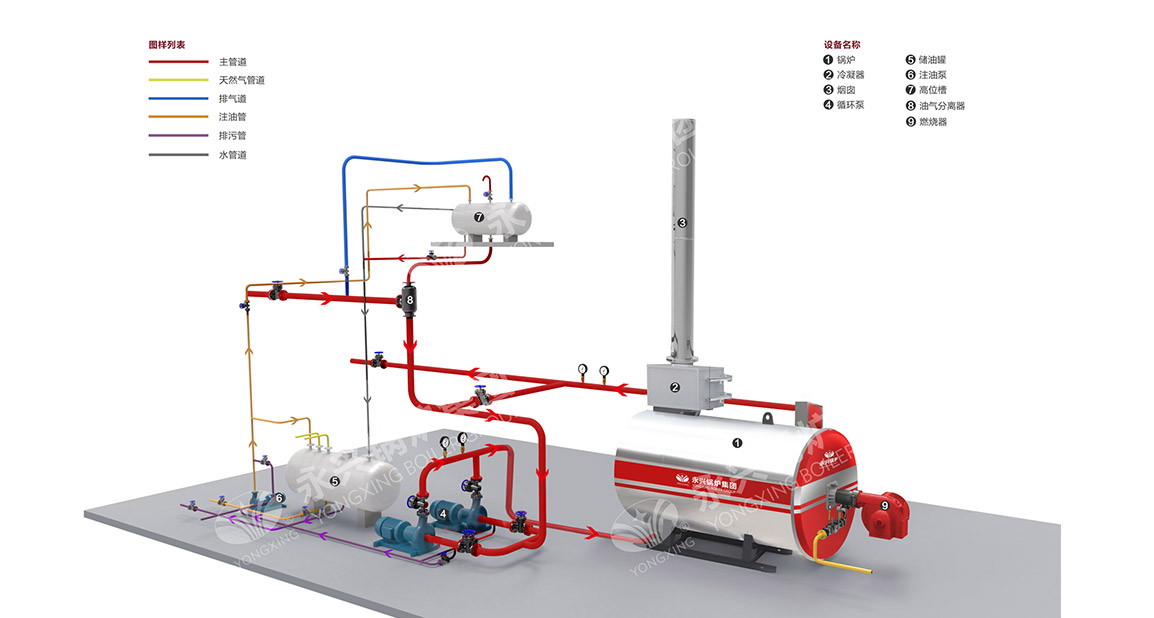

Combustion System: include: oil storage (gas) tanks, burners, combustion chambers, air preheaters, chimneys, etc.

The heating system includes: furnace body, oil storage tank, expansion tank, circulating pump (one of the two is reserved), oil injection pump, filter, oil and gas separator, etc.

The electrical system includes: an electrical controller and its measuring instruments.

Thermal Oil Boiler

- Thermal Power: 120KW-1000KW

- Rated Pressure: 0.7/1.0 Mpa

- Oil Temperature: 290/310 ℃

- Thermal Efficiency: >83%

- Capacity: 1400KW-7000KW

- Pressure: 1.1 Mpa

- Max Temperature: 320 ℃

- Thermal Efficiency: 83%

- Thermal Power: 240KW-7000KW

- Rated Pressure: 0.8/1.0 Mpa

- Oil Temperature: 300/320 ℃

- Thermal Efficiency: 94%

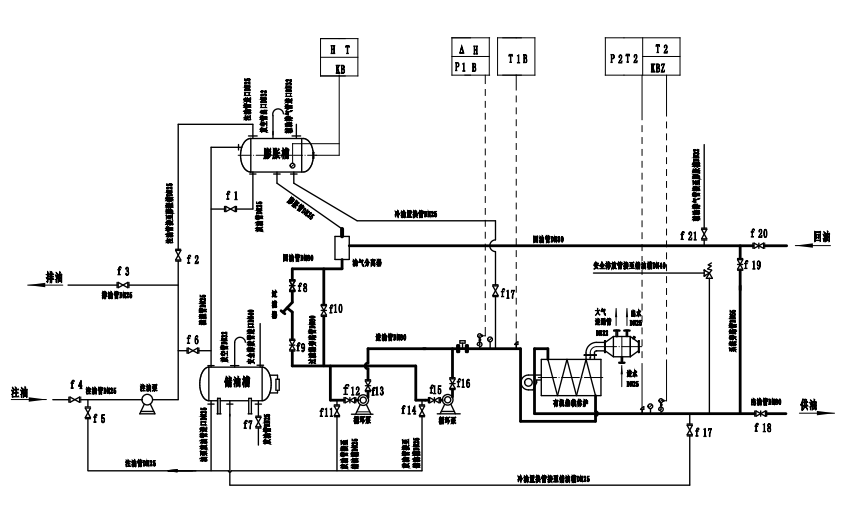

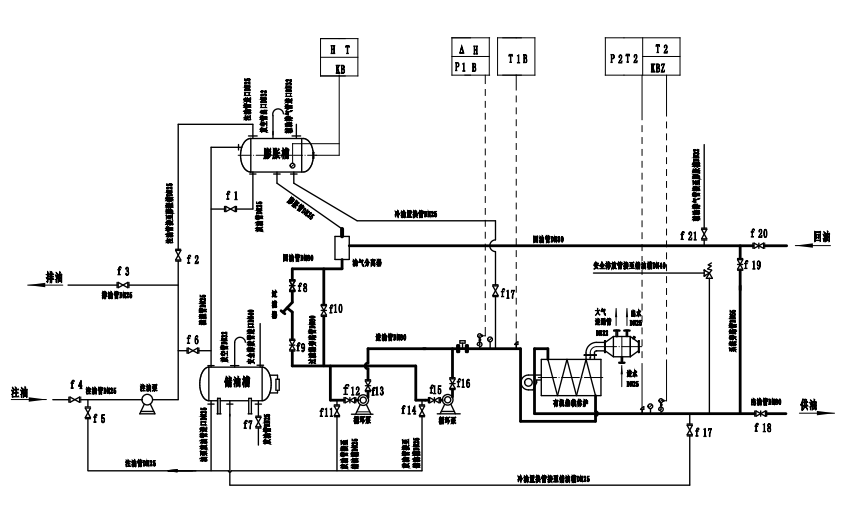

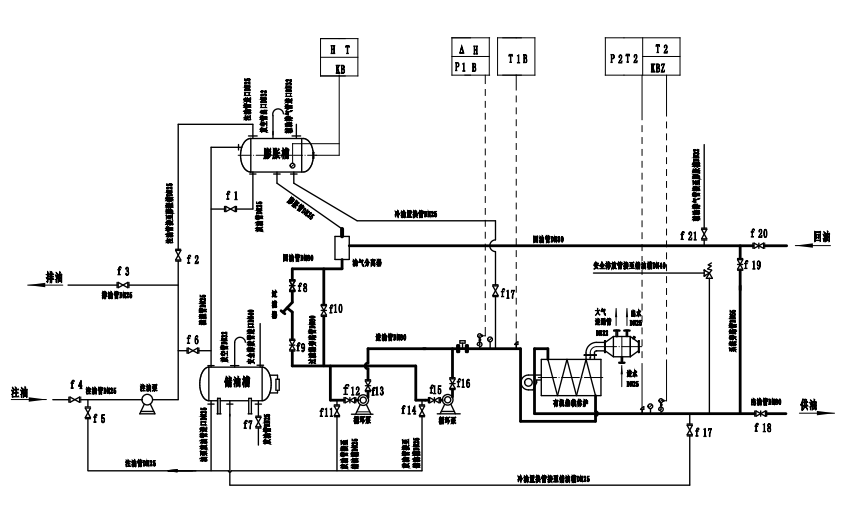

Thermal Oil Heating System Process Flow

- Oil Feeding: Feed heat transfer oil into the thermal fluid heating system. The oil source is provided by the external or oil storage tank.

- Oil Circulation: the heating medium oil is heated to the required temperature and transfer thermal energy to the heating equipment. It consists of a oil circulating pump, a heating oil furnace, heating equipment, an oil vapor separator, a filter and its connecting pipes and valves.

- Cold Oil Replacement: In order to prevent the thermal oil in the furnace tube from overheating during emergency shutdown, close the system valve and open the replacement valve. The expansion tank, oil and gas separator, oil furnace and its connecting pipes will replace the hot oil in the oil furnace to the oil storage tank.

- Excess oil from overflow, exhaust, and expansion tanks automatically flows into oil storage tanks and expansion tanks through pipes, and the gas in the oil storage tanks is vented to safety zones through vent pipes.

- Display temperature, pressure and differential pressure. Indicate the circulation of heat transfer oil in the system and reflect whether the heating system works normally.

- Auxiliary exhaust: When the heat transfer oil is in the initial dehydration phase, when the air volume is large, the auxiliary exhaust valve and pipeline can be used for auxiliary exhaust. At this time, the vent tube valve on the expansion tank should be closed to prevent the heat transfer oil from being washed away by the gas. The vent tube spouted. When the heating furnace works normally, the auxiliary valve is closed to open the vent pipe valve, and the trace gas generated in the system is discharged through the exhaust pipe through the oil-gas separator.

- Bypass: When the supply of thermal power to the heating equipment is stopped, the bypass valve is opened. When the bypass valve is closed during normal work, the expansion pipe plays the role of thermal expansion overflow of the heat transfer oil and automatic compensation;

- Safety protection devices should be installed when the boiler and system oil injection volume exceeds 5m3.

Introduction of The Overall Thermal Fluid Heating System

Thermal Equipment

The required temperature of the material being heated in the thermal equipment determines the working temperature of the heat transfer oil. The heat transfer oil's temperature should be higher than the temperature of the material being heated. The larger the temperature difference, the smaller the heating area required, and the larger the temperature difference will inevitably make the heat transfer. The oil temperature is high, and some chemical materials are easy to crack and coke at high temperatures. Therefore, the temperature difference should be determined according to the specific situation, so as not to make the thermal fluid exceed the maximum use temperature or damage the heated material.

Thermal Fluid Heating System

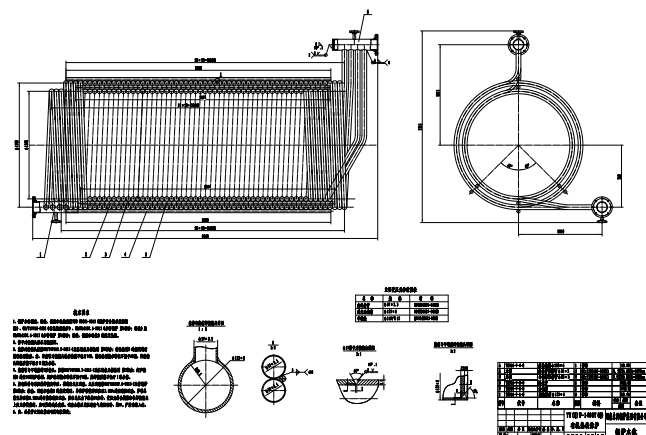

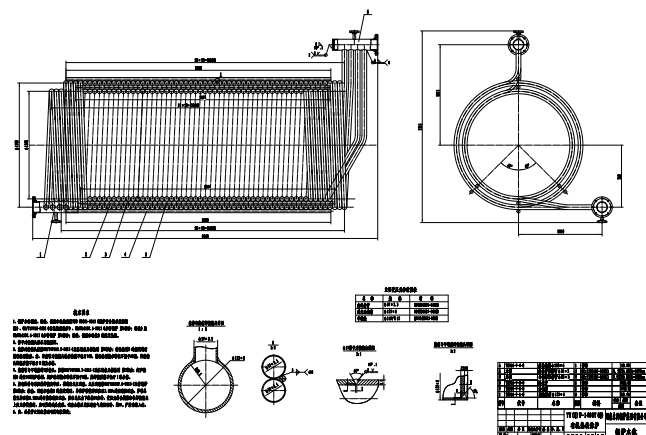

The thermal fluid heater is the key equipment of the heating system. The main body generally use tube furnaces. In order to avoid over-temperature coking, the flow rate of the heat transfer oil in the furnace tube should not be too slow, high speed flow rate will increase the flow resistance and consume more pump heads and power.

Thermal fluid boiler exhaust temperature is relatively high, generally in the 300-400 ℃ larger furnace type should be added air preheater or energy saver to improve thermal efficiency and save energy consumption.

Oil Expansion Tank

The expansion tank is used to compensate the volume change of the heat transfer oil due to temperature changes, it can help the system dehydrate and exhaust steam. Therefore, the expansion tank should be set at an elevation of 3 meters above the heating system. The expansion tank is a normal-pressure container, and is provided with an exhaust discharge opening communicating with the atmosphere, an overflow port, and a low-level alarm device for ensuring the safe operation of the system.

Oil Filter

The oil filter is used to filter and remove foreign matter and coke from the system. Generally use metal wire mesh for coarse filtration. However, coke particles and a small amount of high polymers are also generated due to local overheating during the heat transfer oil heating operation. In order to improve the service life of heat transfer oil and organic heat carrier furnaces, stainless steel powder metallurgy filter elements can be used as fine filtering devices.

Oil Circulation Pump

Our thermal oil heating system adopts RY series hot oil circulation pump, which has reliable sealing and no leakage. It is the power of forced circulation of the heat-conducting oil boiler. Two hot oil circulation pumps are required for each hot oil heating system.

Oil Storage Tank

The oil storage tank is mainly used to store the thermal oil discharged from the expansion tank, the furnace tube and the system. It should be in a low liquid level during normal work and ready to store external heat transfer oil. The exhaust port should be connected to a safe area and no valve should be provided.

Oil Gas Separator

Oil-gas separator: It is used to separate air, steam and non-condensable gas in the system, and it is introduced into the expansion tank and discharged. The installation height and horizontal inlet and outlet are at least flush with the highest point of the pipeline.The expansion tank is a normal-pressure container, and is provided with an exhaust discharge opening communicating with the atmosphere, an overflow port, and a low-level alarm device for ensuring the safe operation of the system.

Safty Valve

The safety valve should be installed on the inlet pipeline of the organic heat carrier furnace, the discharge port should be connected to the oil storage tank, and no valve should be set between the furnace body and the furnace body to prevent the heat transfer oil from overheating due to the valve's misoperation.

Oil Feeding Pump

The oil feeding pump is used for supply oil to the circulation system, and generally a cold oil gear pump is used.

Auxiliary Equipment

Please refer to the corresponding instruction manual for use.

Thermal Oil Heater Application Industry

- Petrochemical industry: polymerization, melting, condensation, distillation, de-H2, forced insulation.

- Oil industry: fatty acid distillation, oil decomposition, concentration, esterification, vacuum deodorization.

- Textile printing and dyeing industry: heat setting, hot melt dyeing, baking, calendering, drying, hot air stentering.

- Plastic and rubber industry: hot pressing, hot rolling, extrusion, vulcanization, calendering, injection molding machine, glue mixer, conveyor belt dryer.

- Papermaking industry: drying, corrugated paper processing, calendering, rubberized rollers.

- Wood industry: Thermal oil heater to make plywood, MDF hot pressing, wood drying, steaming equipment.

- Building materials industry: gypsum board drying, asphalt heating, asphalt concrete, emulsified asphalt, concrete component maintenance, drying equipment, linoleum production lines.

- Machinery industry: spray paint printing drying, assembly processing, cleaning and drying.

- Food industry: baking bread, drying biscuits, cooking pots, autoclaves, conveyor belt dryers.

- Air-conditioning industry: heating of industrial plants and civil buildings.

- Electrical equipment industry: calender, platen press, vacuum pot, dryer.

- Coking industry: gas storage tank, mixing station, distribution station.

- Metal and foundry industry: degreasing tank, phosphate processing equipment, baking machine (room), sand core drying.

- Detergent industry: cooking pots, autoclaves, conveyor dryers, lipolysis equipment, distillation towers.

- Fat and paint industry: autoclave, dryer, retort, cooking equipment.

- Automobile industry: tunnel drying room, degreasing bath, phosphate treatment equipment.

- Carbon industry: graphite electrodes, carbon products, asphalt melting, kneading pot heating, extrusion molding.

Thermal Oil Heater Manufacturing Equipment